Manufacturing

Prototyping

Katech maintains a full-service CNC facility that provides one-off designs and small runs of prototypes that assist corporate clients with design revisions, functionality, and cost-reduction strategy.

Katech can build from metal, plastic, or composite materials. We are known for quick turnaround and extreme quality.

Katech CNC resources include a Centroid A560, Hass VF6 5-Axis VMC; Haas VF5 5-Axis VMC; Hass VF4SS 4-Axis VMC; Fadal 15XT-4-Axis VMC; Haas VF3 4-Axis VMC; Fadal 4020-4-Axis VMC; a Haas VF2-SS-4-Axis VMC; Haas VF2 3-Axis VMC; Haas SL-20T Lathe with C-axis; Haas SL-10 Big Bore Lathe; and Haas SL-20- Lathe, with bar feeder and live tooling.

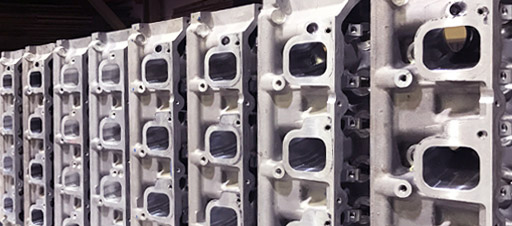

Manufacturing

Katech provides short- and long-run manufacturing services delivering engine and vehicle components to the most demanding specifications. Whether it’s a thousand parts or a hundred thousand – from simple piece parts to complex prismatic parts requiring four- and five-axis machining – Katech manufacturing consistently delivers on time and to the highest level of quality.

Engine Build

Katech provides OEMs engine development and testing solutions that can significantly reduce product development time and cost.

Katech’s rigorous assembly process covers pre-assembly measurements, clearances, assembly procedures, torques, adhesives, lubricants and other aspects of engine assembly. Traceable records are maintained for future reference. Quality control is maintained through progressive inspection and procedures.

Click here to see all the Katech build steps

- Disassemble, wash and inspect parts

- Crack check using Magnaflux (ferrous metals) or Zyglo (non-ferrous metals) if necessary

- Chase all threads in cylinder case and clean

- Measure main bores, line hone if necessary

- Measure lifter bore clearance

- Measure cylinder bore

- Hone cylinder bores using deck plates

- Measure bore finish with profilometer

- Weigh pistons, connecting rods, rod bearings, pins, locks and rings to determine crankshaft bobweight

- Balance crankshaft

- Polish crankshaft journals

- Tack weld crankshaft trigger wheel

- Hone piston pin bores and connecting rod small end

- Polish piston pins (excl. DLC-coated pins)

- Deburr piston round wire locks

- Measure ring lands for back clearance

- Deburr piston ring ends

- Gap piston rings

- Measure main journals with air gauge

- Measure big end of connecting rods with air gauge, hone if necessary

- Size main bearings with air gauge

- Measure connecting rod bolt stretch

- Size rod bearings with air gauge

- Measure crankshaft endplay

- Measure piston pin endplay

- Measure connecting rod side clearance

- Check piston to deck height

- Deck block if neces

- CC piston dome volume

- CC cylinder head chamber volume

- Deck heads if necessary

- CC intake port volume

- CC exhaust port volume

- Measure valve guide clearance

- Measure valve spring pressure and coil bind

- Check valve spring retainer to seal clearance

- Polish camshaft

- Measure camshaft specs with EZ Cam

- Degree camshaft

- Measure piston-to-valve clearance

- Measure valve radial clearance

- Measure vertical valve drop

- Measure camshaft endplay

- Measure lifter preload to determine pushrod length

- Calculate compression ratio

- Torque all fasteners to spec

- Document all measurements and torques in engine build book

- Perform engine dynamometer validation

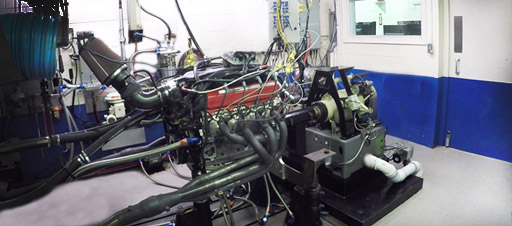

Engine Testing

Katech maintains three Engine Dynamometers Cells geared for performance applications. Two are rated over 12,000 RPM and 1000 horsepower, the third cell is rated at 12,000 RPM and 3,000 horsepower. All cells operate with multiple fuels, allowing calibration over a wide-range of applications.

The Katech Motoring Cell measures parasitic losses for a range of engine components. The Katech Valvetrain Cell provides physical testing, from cam to valve actuation. The Katech Fuel Flow Cell tests fuel system configurations prior to first application.

The six test cells are also used to provide several other critical engine tests, including cylinder pressure and engine air flow.

Holelocc

Katech Corporate Services is also focused on the needs of other markets that benefit from our expertise in engineered machining solutions. One such market is correctional facilities.

Hanging is a common form of suicide in jails and prisons, and drain holes in inmate beds can be used for hanging. HoleLocc, one of Katech’s latest corporate products, eliminates the opportunity.

Each Holelocc plug is precision CNC-machined from American steel, built to last. The patent-pending design is highly engineered so it cannot be removed by an inmate. And, critical to correctional operations, HoleLocc is rapidly installed with minimal disruption to daily routine.