Motorsports

Programs

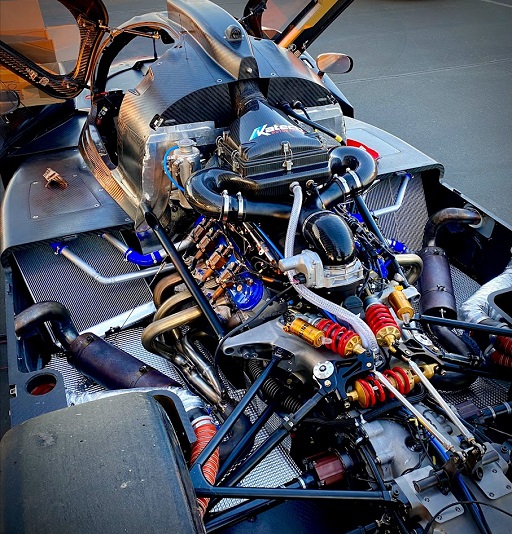

Katech works with management of an existing or new race series to develop vehicle packages, series spec engines, conformance testing, engine control software, team training, track support, and overall process improvements.

On demand, Katech can then follow through with program management for the series, ensuring that inventory, testing, technicians, and other resources are in place to keep the series running smoothly.

Engine Development

Katech draws on its 40 years of racing to develop engines that meet exacting performance requirements and regulations. We maintain a full-service CNC laboratory and six test laboratories to modify existing engines to series spec, and to validate performance.

GM built its legendary Corvette Racing Program on the insight and technical innovation of Katech engine developers and builders. That same expertise continues to be sought today by race series throughout the world.

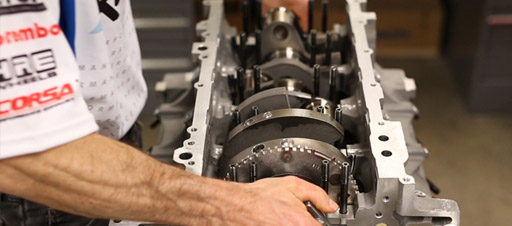

Engine Build

If you need an engine built, Katech has the master engine builders to meet your needs and surpass your expectations. Katech engines are assembled using a rigorous 48-step process that is documented and kept on file at Katech for the life of the engine.

To meet the most demanding performance requirements, Katech performance testing labs are available, as required, to provide valvetrain dynamics testing; cylinder head flow testing; dynamometer durability testing and track simulation; engine calibration (MEFI4); and much more.

The Katech engine build lab is further supported by a complete machine shop.

Click here to see all the Katech build steps

- Disassemble, wash and inspect parts

- Crack check using Magnaflux (ferrous metals) or Zyglo (non-ferrous metals) if necessary

- Chase all threads in cylinder case and clean

- Measure main bores, line hone if necessary

- Measure lifter bore clearance

- Measure cylinder bore

- Hone cylinder bores using deck plates

- Measure bore finish with profilometer

- Weigh pistons, connecting rods, rod bearings, pins, locks and rings to determine crankshaft bobweight

- Balance crankshaft

- Polish crankshaft journals

- Tack weld crankshaft trigger wheel

- Hone piston pin bores and connecting rod small end

- Polish piston pins (excl. DLC-coated pins)

- Deburr piston round wire locks

- Measure ring lands for back clearance

- Deburr piston ring ends

- Gap piston rings

- Measure main journals with air gauge

- Measure big end of connecting rods with air gauge, hone if necessary

- Size main bearings with air gauge

- Measure connecting rod bolt stretch

- Size rod bearings with air gauge

- Measure crankshaft endplay

- Measure piston pin endplay

- Measure connecting rod side clearance

- Check piston to deck height

- Deck block if necessary

- CC piston dome volume

- CC cylinder head chamber volume

- Deck heads if necessary

- CC intake port volume

- CC exhaust port volume

- Measure valve guide clearance

- Measure valve spring pressure and coil bind

- Check valve spring retainer to seal clearance

- Polish camshaft

- Measure camshaft specs with EZ Cam

- Degree camshaft

- Measure piston-to-valve clearance

- Measure valve radial clearance

- Measure vertical valve drop

- Measure camshaft endplay

- Measure lifter preload to determine pushrod length

- Calculate compression ratio

- Torque all fasteners to spec

- Document all measurements and torques in engine build book

- Perform engine dynamometer validation

- Hot hone (cylinder bore honing at operating temperature)

- Piston ring land flatness measurement to the millionth of an inch

- Hardness testing

- Bore cylindricity measurement using PAT Incometer

- Valvetrain dynamics testing

- Cylinder head flow testing

- Dynamometer durability testing and track simulation

- Engine calibration (MEFI4)

Track Support

Katech track support ensures that everything for the team and/or the series is running properly – with services from problem solving to engine tuning to ideas for continuous improvement.

A key part of Katech track support is race data acquisition and analysis, and calibration support for several data acquisition systems:

- AIM Sports

- MEFI 4

- Magneti Marelli

- Bosch MS

In addition, the Katech WHISTLER is a proprietary electronic device that instantly determines the compression ratio of virtually any engine. Whistler is used by NASCAR and SCCA.